Up: Glassmaking

How Bottles Made

9 of 18

|

|

| |

|

When green glass is wanted, limestone is used. Both amber and

emerald green glass consist of the same materials as the green

batch, but to the amber, coke, charcoal, manganese, ferric oxide,

sulphur and salt must be added, while the emerald green is

completed with coke, sodium bichromate and cobalt.

Glass melts at a temperature of from 2500 to 2700 degrees

Fahrenheit. During the melting and refining processes,

constant watchfulness is required. One problem is to keep

the coarser elements from separating from the finer ones in

the batch. Another is that of the viscosity of the molten

glass. This is kept at the proper point by keeping the

temperature at approximately 2000 degrees with the aid of

an optical pyrometer. At this temperature it is at the proper

consistency to be fed from the feeder into the machines.

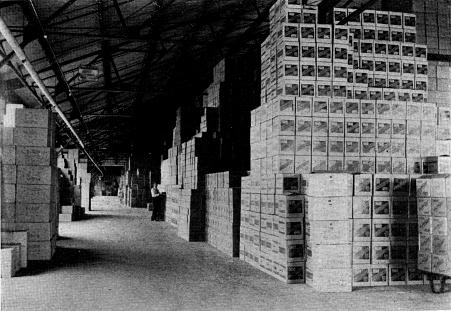

Here is one of the warehouses in which Whitall Tatum

Company bottles are stored pending shipment. The storage

capacity runs into millions of bottles. Dry storage is an

unusual but necessary feature in bottle manufacture, for long

ago, we discovered that glass subjected to to the elements

tends to deteriorate. Strangely enough, moisture is

particularly to be avoided. Gasoline and electric tractors

fly in and out of these long aisles, stocking fresh supplies

or carting them away to the nearby rail siding.

|

|