|

Prism Glass Types |

|

| Prism Glass Makers |

|

|

Reference |

|

|

Repair/Restoration |

|

|

Construction |

|

|

Collection Gallery |

|

|

In Situ Gallery |

|

Don't Grope About in the Dark

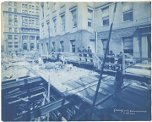

Vault lights construction

New York City, 1907

Display of vault lights,

deck prism, coal plates, etc.

Illuminated sidewalk lift

Etna, California, 2010

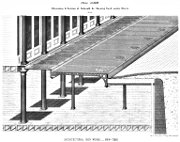

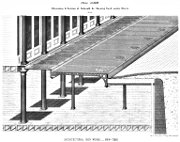

Sidewalk Vault (Plate LXXXIII),

Badger's Illustrated Catalogue

of Cast-Iron Architecture

Lith. of Sarony, Major & Knapp

449 Broadway, NYC

|

|

|

|

|

|

Penn Station, 1938

|

Prism glass is architectural glass used to redirect daylight

(sunlight and skylight) into interior spaces through refraction and

reflection— "daylighting". Before electric lighting became

common around 1900, light was provided free of charge by the sun, but

at night by candle, lamp, or other flame.

Penn Station

(right) was a glorious example: the glass roof let in sunlight which fell

through the glass-embedded floor to illuminate the tunnels below.

Since sunlight is the superior light source, while flames are dim,

smelly, smoky, expensive and dangerous, anything which could extend

the reach of the sun's free and safe light to interior spaces would

make that space more useful and valuable.

Group of original deck lights,

bottoms shown (tops are flat)

|

|

Deck lights were the first form of prism glass—

the earliest known patent is Wyndus' of 1684: GREAT AND DURABLE INCREASE OF LIGHT BY EXTRAORDINARY GLASSES AND LAMPS;

sadly, the details are not specified. Fire at sea is disaster, more so

on a wooden ship or with a flammable cargo. Safely lighting a ship's

interior with daylight and prisms instead of flames was a practice widely

adopted. Colliers and

lime

cargos were especially dangerous (slaking lime becomes very hot).

The glasses work both directions: they daylight the hold, but also show on

deck any light from a cargo fire.

Before: open grate |

Eventually the idea was adapted for land use as

vault lights (UK pavement lights).

Light used to be provided to vaults and basements by open grates, which were

difficult to walk on (especially with women's shoes) and obviously let in

water. By placing glass lenses in an iron (or later concrete) frame, daylight

could be introduced below while excluding the weather. Iron nubs

protruding above the glass surface protect the glass and aid traction. |

After: vault lights |

In 1834, Edward Rockwell patented a round iron plate

with a single large lens, but Hyatt later complained in his own patent

application, "These glasses are extremely liable to fracture, and when broken leave large and dangerous openings within their rims...".

Rockwell's plates are rare today; I know of only three examples of the iron

covers and none of the lenses.

As an improvement on Rockwell's design, Thaddeus Hyatt

in 1845 patented his Vault Cover,

an illuminated iron plate set with numerous small, tougher bulls-eye lenses,

protected with protruding iron knobs. His Hyatt Lights worked well

and were a hit; they made him a rich man. From the 1850s on, Hyatt spent

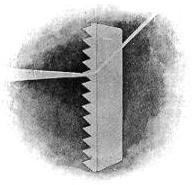

much of his time and fortune fighting for abolition of slavery.  The next big advance was Hayward Brothers' 1871 Improvements in Pavement Lights. Pendant prisms had been tried before but did not work well.

Edward Hayward's idea was to use a semi-prism shape instead: "...the

object of my Invention is so to construct them [prisms] that they may not

simply allow the light to pass through, but that they may also direct the

light in an inclined direction into the rooms it is desired to light."

Using a combination of internal reflection and refraction, the prisms

could re-direct and disperse light from the vertical to the horizontal,

throwing light from the one bright area deep into the backs of otherwise

useless spaces.

The next big advance was Hayward Brothers' 1871 Improvements in Pavement Lights. Pendant prisms had been tried before but did not work well.

Edward Hayward's idea was to use a semi-prism shape instead: "...the

object of my Invention is so to construct them [prisms] that they may not

simply allow the light to pass through, but that they may also direct the

light in an inclined direction into the rooms it is desired to light."

Using a combination of internal reflection and refraction, the prisms

could re-direct and disperse light from the vertical to the horizontal,

throwing light from the one bright area deep into the backs of otherwise

useless spaces.

Prism tile bending light

|

The most familiar type of prism glass are prism tiles,

which take the reflection/refraction idea of semi-prism vault lights and

applies it to vertical windows.

American 3-Way Prism Co

Trademark tile

|

They were based on James G. Pennycuick's 1885 patent

for window glass with horizontal prisms on the inner surface, and introduced

commercially in 1897 by the Luxfer Prism Company.

They were an instant success and the tiles were very widely used. Prism tile

installations can still be seen in many small towns where they were especially

popular as transom lights above storefront windows. Like vault lights, prism

tiles take concentrated light from the sky which falls at the front of a room

and redirects and diffuses it to the darker parts of a space.

Sometimes called generically "Luxfer tiles", they were also made by the

American 3-Way Prism Co

(with whom they later merged), Solar Prism Co,

Condie-Neale Glass Co,

Berger Manufacturing Co and others.

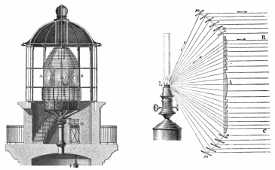

How a Fresnel lighthouse lens bends light

|

The Fresnel lens was developed by

Augustin-Jean Fresnel

in 1822 for magnifying lighthouse lanterns. It is essentially the

outer surface of a double-convex lens, but without the core glass.

It works the same as a solid lens would, and makes it possible to

build compound lenses much larger than a single lens could ever be.

There is much about Fresnel elsewhere, so

I won't duplicate here.

|

1st Order Fresnel,

SF Maritime

Photo: NPS

|

|

Steam boiler gage glasses look like skinny desk prisms. The plain style

are just solid glass, but the "reflex" type (right) have prisms on the steam

side:

"Type B, Reflex, is made for extra ease in locating liquid levels.

This gage glass has vertical prisms extending the full viewing length of

the glass. The prism side faces the liquid. The sections of the prisms

covered with liquid do not reflect light. The sections of the prisms not

covered with liquid reflect light brilliantly. Thus the liquid level

stands out extra clearly from a great distance away."

Of the MACBETH brand (made by Corning), the smallest is #1 at 4½"

long, and the largest the #9 at 13 3/8" long. Pictured is #8,

which is 12 5⁄8" long,

1 5⁄16" wide, and

11⁄16" thick. Marked on one side (by dulling the glass,

either sandblasting or acid etch) "TYPE B-8 / REFLEX" where / indicates a

line break. The other side reads "MACBETH ® BRAND /

ALUMINOSILICATE / MADE IN U.S.A."

See the MacBETH gage glass instruction sheet.

|

|

|